2 WAY BREECHING INLET CABINET

| Specifications | |

|---|---|

| Dimension | 600mm x 400mm x 300mm |

| Material | Mild Steel |

| Thickness | 0.9mm |

| Installation | Clear Type |

| Capacity | Recess Mounted |

| Paint Finish | Epoxy Powder Red |

| Manufacture | BS 5041 Part 5 |

| Code No. | MF-MS-STD-RD |

4 WAY BREECHING INLET CABINET

| Specifications | |

|---|---|

| Dimension | 600mm x 400mm x 300mm |

| Material | Mild Steel |

| Thickness | 0.9mm |

| Installation | Clear Type |

| Capacity | Recess Mounted |

| Paint Finish | Epoxy Powder Red |

| Manufacture | BS 5041 Part 5 |

| Code No. | MF-MS-004-RD |

LANDING VALVE CABINET

| Specifications | |

|---|---|

| Dimension | 400mm x 600mm x 300mm |

| Material | Mild Steel |

| Thickness | 1.2mm |

| Installation | Clear Type |

| Capacity | Recess Mounted |

| Paint Finish | Epoxy Powder Red |

| Code No. | MF-MS-LVD-RD |

DOUBLE COMPARTMENT PIVOT TYPE HOSE REEL CABINET

| Specifications | |

|---|---|

| Dimension | 750mm(w) x 1550mm(H) x A(D) |

| Material | Mild Steel |

| Thickness | 1.5mm(Door), 1.2mm(Body) |

| Installation | Surface/Wall Mounted, Recessed |

| Capacity | Manual or Automatic Fixed Type Hose Reel %" or 1", & 2pcs Fire Extinguisher |

| Paint Finish | Epoxy Powder Red / White, 70 micron min. |

| Code No. | Dimension A (Depth) mm | Type |

|---|---|---|

| MF-MS-420-WH | 420 | Surface / Wall Mounted (19? Drum) |

| MF-MS-420-WH | 420 | Surface / Wall Mounted (22? Drum) |

| MF-MS-420-WH | 420 | Recessed (19? Drum) |

| MF-MS-420-WH | 420 | Recessed (22? Drum) |

Double Compartment Hose Reel Cabinet

| Specifications | |

|---|---|

| Dimension | 740mm(w) x 1540mm(H) x A(D) |

| Material | Mild Steel |

| Thickness | 1.2mm |

| Installation | Surface/Wall Mounted, Recessed |

| Capacity | Manual or Automatic swing Hose Reel %" or 1", & 2pcs Fire Extinguisher |

| Paint Finish | Epoxy Powder Red / White, 70 micron min. |

SINGLE COMPARTMENT PIVOT TYPE HOSE REEL CABINET

| Specifications | |

|---|---|

| Dimension | 1000mm(w) x 800mm(H) x A(D) |

| Material | Mild Steel |

| Thickness | 1.2mm |

| Installation | Surface/Wall Mounted, Recessed |

| Capacity | Manual or Automatic swing Type Hose Reel %" or 1", & INo. Fire Extinguisher 9kg |

| Paint Finish | Epoxy Powder Red / White, 70 micron min. |

DOUBLE COMPARTMENT HOSE REEL CABINET

| Specifications | |

|---|---|

| Dimension | 750mm(w) x 800mm(H) x A(D) |

| Material | Mild Steel |

| Thickness | 1.2mm Body, 1.5mm Door |

| Installation | Surface/Wall Mounted, Recessed |

| Capacity | Manual or Automatic Hose Reel Fixed Type %" or 1", Hose up to 36m |

| Paint Finish | Epoxy Powder Red / White, 70 micron min. |

HOSE REEL CABINET

| Specifications | |

|---|---|

| Dimension | 600mm x 600mm x 350mm |

| Material | Mild Steel |

| Thickness | 0.9mm |

| Installation | Wall Mounted |

| Capacity | 2 Nos Diffuser Nozzle, 2 Length of Hose 2-1/2" x 30m (Type 1) |

| Paint Finish | Epoxy Powder Red |

| Code No. | MF-MS-MDX-RD |

HOSE CABINET

| Specifications | |

|---|---|

| Dimension | 600mm x 600mm x 350mm |

| Material | Mild Steel |

| Thickness | 0.9mm |

| Installation | Wall Mounted |

| Capacity | 2 Nos Diffuser Nozzle, 2 Length of Hose 2-1/2" x 30m (Type 1) |

| Paint Finish | Epoxy Powder Red |

| Code No. | MF-MS-MDX-RD |

DOUBLE COMPARTMENT HOSE REEL CABINET

| Specifications | |

|---|---|

| Dimension 800mm (W) x 1000mm (H) x 300mm (D) Material Mild Steel Thickness 1.2mm Installation Wall Mounted |

HOSE CABINET

| Specifications | |

|---|---|

| Dimension 800mm (W) x 1000mm (H) x 300mm (D) Material Mild Steel Thickness 1.2mm Installation Wall Mounted |

2WAY BREECHING INLET

MODEL: KX08-202-00

| Size | H (mm) | W (mm) | D (mm) | Connections |

|---|---|---|---|---|

| DN | 225 | 300 | 100 | 2xBS336 |

| DN | 225 | 300 | 100 | 2x2.5BSP |

4 WAY BREECHING INLET

MODEL: KX08-202-00

| Size | H (mm) | W (mm) | D (mm) | Connections |

|---|---|---|---|---|

| DN150 | 215 | 330 | 150 | 4xBS336 |

| DN150 | 215 | 330 | 150 | 4x2.5BSP |

DRY BARREL FIRE HYDRANT

| Specifications |

|---|

|

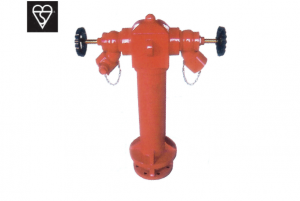

2 WAY WET PILLAR HYDRANT

| Specifications | |

|---|---|

| Body material | Cast Iron to BS 1452 |

| Inlet | 4" Table T BS 10 Flange |

| Outlet | Copper Alloy 2x2.5" Control Valve with Female BS Inst. Outlet |

| Working pressure | 20bar(290 psi) |

| Adaptor | Brass /LG2(Gun Metal) |

| Paint Finish | Red & Yellow Epoxy Coated |

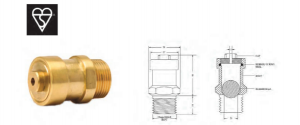

AIR RELEASE VALVE

| Specifications | |

|---|---|

| Model no. | BFE090203 |

| Thread Type | Male BSPT |

| Body | Brass |

| Description |

|---|

| An air release valve is fitted at the highest point in the installation to allow air to discharge when the rising main is filled and for air to enter when the rising main is drained. This is to vent entrained air that collects at high points in the riser. The standard inlet connection is male BSPT screw. Other thread, eg., NPT is available on request. The air release valve is generally installed in a Dry Riser System but it can also be used in wet systems such as Wet Riser, Automatic Sprinkler and Fire Hose reel Systems. The maximum hydraulic test pressure is 300 PSI and recommended working pressure is 175 PSI. |

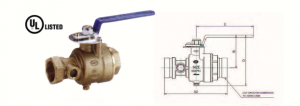

ANGLE HOSE VALVE, UL LISTED

MODEL: MY_DF_40

Specifications

The angle (90 degree) pattern valve for use on standpipe having inlet and outlet opening of the same size or with the inlet larger than outlet. Opening was the 172 - 21/2 inch nominal size.

The valve is made in accordance with UL 688 Hose valve for Fire Protection service.

| Model | Size | Inlet | Outlet |

|---|---|---|---|

| MY_DF_40 | 11/2X 11/2 | V/2 Female NPT | V/2 Female NPT |

| MY_FM_40 | V/2X 1’/2 | V/2 male NST | V/2 male NST |

| My_DF_65 | 272 x 272 | 2V2 Female NPT | 272 Female NPT |

| My_FM_65 | 272 x 272 | 272 Female NST | 272 male NST |

The above models, body is made of material cast brass to ASTM B584 C85700, Hand wheel material ductile cast iron to ASTM A536 60-40 18, seat seal NBR compound #E701 N

Option extra: Female NST thread cap and chain.

Marking: UL listed 3S59 V/2 / 272 MYFFCO HOSE VALVE 300

Rated pressure 300 psig. test pressure 600psig

MODEL: SINGLE JACKET

FIRE HOSE ZY FIRE, UL LISTED

| Specifications: | |

|---|---|

|

Model |

: 17-40,1-1/2" Single jacketed fire hose fori nterior standpipes with TPU lining, hot melting adhesive and polyester jackets. |

|

Jacket |

: 100% virgin Polyester jacket, Single Jacket Twill or plain weave |

|

Lining |

: Polyurethene (TPU) cube. |

|

Color |

: White, Red, Yellow. |

|

Package |

: Roll or folded, packed in carton or loaded in pallet. |

|

Application |

: non-percolating uncoated rack hose, also named as Box hoses, Cabinet Hoses, Rack hoses are placed in cabinet located in residential, industrial building, Premium solution. |

|

Hose Standard |

: meet or exceed UL219, ULC. |

|

Standard length |

: 15m (50ft), 20m (66ft), 22m(75ft), 30m (100ft). |

| I.D | Service Pressure | Minimum Burst Pressure |

|---|---|---|

| Inch mm | (PSI/Bar) | (PSI/Bar) |

| 2’/2"55 | 400/28 | 1200/84 |

MODEL: DOUBLE JACKET

EPDM LINING FIRE HOSE ZY FIRE, UL LISTED

| Specifications: | |

|---|---|

|

Model |

: 17-40,1-1/2" Single jacketed fire hose fori nterior standpipes with TPU lining, hot melting adhesive and polyester jackets. |

|

Jacket |

: 100% virgin polyester Jacket, Double Jacket, Twill or Plain weave high performance in abrasion-resistance. |

|

Lining |

: EPDM rubber tube. |

|

Color |

: White, Yellow, Orange, Red, Blue, Green, Tan. |

|

Package |

: Rolled, packed in cartoon or loaded in pallet. |

|

Hose Standard |

: meet or exceed UL219, ULC. |

|

Standard length |

: 15m (50ft), 20m (66ft), 25 (82ft), 30m (100ft). |

| I.D | Service Pressure | Minimum Burst Pressure |

|---|---|---|

| Inch mm | (PSI/Bar) | (PSI/Bar) |

| 2’/2"55 | 400/28 | 1200/84 |

PORTABLE SPRAY NOZZLE CD FIRE, UL LISTED

|

Specifications: |

|---|

| Model A trade size in 1-1/2"and 2-1/2", rated for use at an inlet pressure of 100 psi, the basic spray type nozzle with a rotational type control, the nozzle is an adjustable type having a water spray discharge ranging from a wide cone shaped pattern through straight stream to shut-off, the nozzle are made of red leaded brass material conforming to ASTM B30, alloy C83600 and utilize EPDM O-ring, the nozzle are intended for use on class A and B fires only, and the discharge rate at 100 psi flowing inlet pressure in full spray pattern 1-1/2"nozzle is 130 ± 5 gpm; 2-1/2" nozzle is 205 ± 5gpm. |

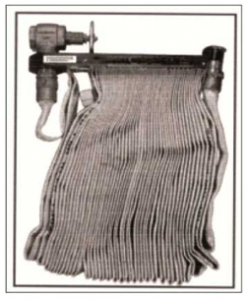

COMPLETE HOSE RACK

|

Specifications: |

|---|

|

Semi-Automatic swing type hose rack UL, ULC/FM Listed. Locking water stop allows valve to be opened without release of water until last fold is removed from rack. |

| MODEL | NO. PINS | FOLDS | LENGTH | VALVE SIZE | CAPACITY |

|---|---|---|---|---|---|

| IE-50 | 15 | 16 | 18" | 1-1/2" | 50' |

| IE-75 | 19 | 20 | 20" | 1-1/2" | 75' |

| IE-100 | 23 | 24 | 22" | 1-1/2" | 100’ |

FIRE PROTECTION THREADED TEST AND DRAIN VALVE CD FIRE, UL LISTED

MODEL: YS-H61

MODEL: YS-H62

| Size | Al ±2 | A2±2 | B±2 | C±2 | D±3 | K |

|---|---|---|---|---|---|---|

| 1" | 128.2 | - | 68.5 | 130.5 | 112 | k4.2/k5.6 |

| 1-1/4" | 128.2 | 161.6 | 68.5 | 130.5 | 12 | k4.2/k5.6 |

| 1-1/2" | 157.2 | 190.9 | 99.1 | 174 | 154 | k4.2/k5.6/k14/k25 |

| 2" | 157.2 | 190.9 | 99.1 | 174 | 154 | k4.2/k5.6/k14/k25 |

WATERFLOW ALARM VALVE SYSTEM CD FIRE, UL LISTED

MODEL: AVD 9110

| Specifications: |

|---|

| AVD 9110 4" Model flanged end vertical installed alarm check valve. Material cast iron ASTM A48 class No. 35. Installation Vertical 1/2 NPT (PT) thread female inlet, % NPT (PT) thread female outlet and 16 NPT (PT) thread female drain. Making UL MODEL A drain on water motor. |

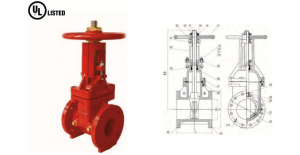

300 PSI OS& YTYPE FLANGED END GATE VALVE, UL LISTED

| Specifications: |

|---|

| 1. Design Standard: AWW A C515 2. Nominal pressure: 300psi 3. Flange Standard: ANSI B6.1 Class 125 or according to the customer's requirements. 4. Both inside and outside of the body need Epoxy Riser Coating. |

| Description: |

|---|

| Material: Cast Iron Pressure: Ordinary Temperature Seal Surface: Wedge Gate Valve Usage: Regulation Application: Industrial Usage, Water Industrial Usage Specification: FM/UL Type: Direct-acting Connection Form: Flange Actuator: Manual Thread Position of Valve Rod: Outside Gate Valve Standard: ANSI Size: 2.5"-12" (Dn65-Dn300) |

PRESSURE RELIEF VALVE

| Description: |

|---|

| The Pressure Relief Valve is designed specifically to automatically relieve excess pressure in fire protection pumping systems. Pilot controlled, it maintains constant system pressure at the pump discharge within very close limits as demands change. |

| Specifications | |

|---|---|

| End Details | 150 and 300 ANSI B16.42 |

| Pressure Ratings | Class 150-250 psi Max. |

| Class 300 - 400 psi Max | |

| Water, to 180°F Max | |

| Standard Materials | Main Valve Body & Cover Ductile Iron ASTM A536 Grade 65-45-12 Standard Main Valve Trim: Bronze Seat, Teflon Coated Stainless Steel Stem, Dura-Kleen Stem Standard Pilot Control System: Cast Bronze with Stainless Steel trim Available in the following relief pressure ranges: |

| Adjustment Range | 20-200 psi (150 Class) 100-300 psi (300 Class) Protective epoxy resin coating of wetted surfaces of main |

| Optional | 1 100-06 Hytrol (Main Valve) 2 CRL-60 Pressure Relief Pilot Valve 3 X44A Strainer & Orifice Strainer 4 81-01 Check Valve 5 Pressure Gauge 6 X46A Flow Clean Strainer |

| BASIC COMPONENTS | Epoxy Powder Red |